EU Customer Shipping

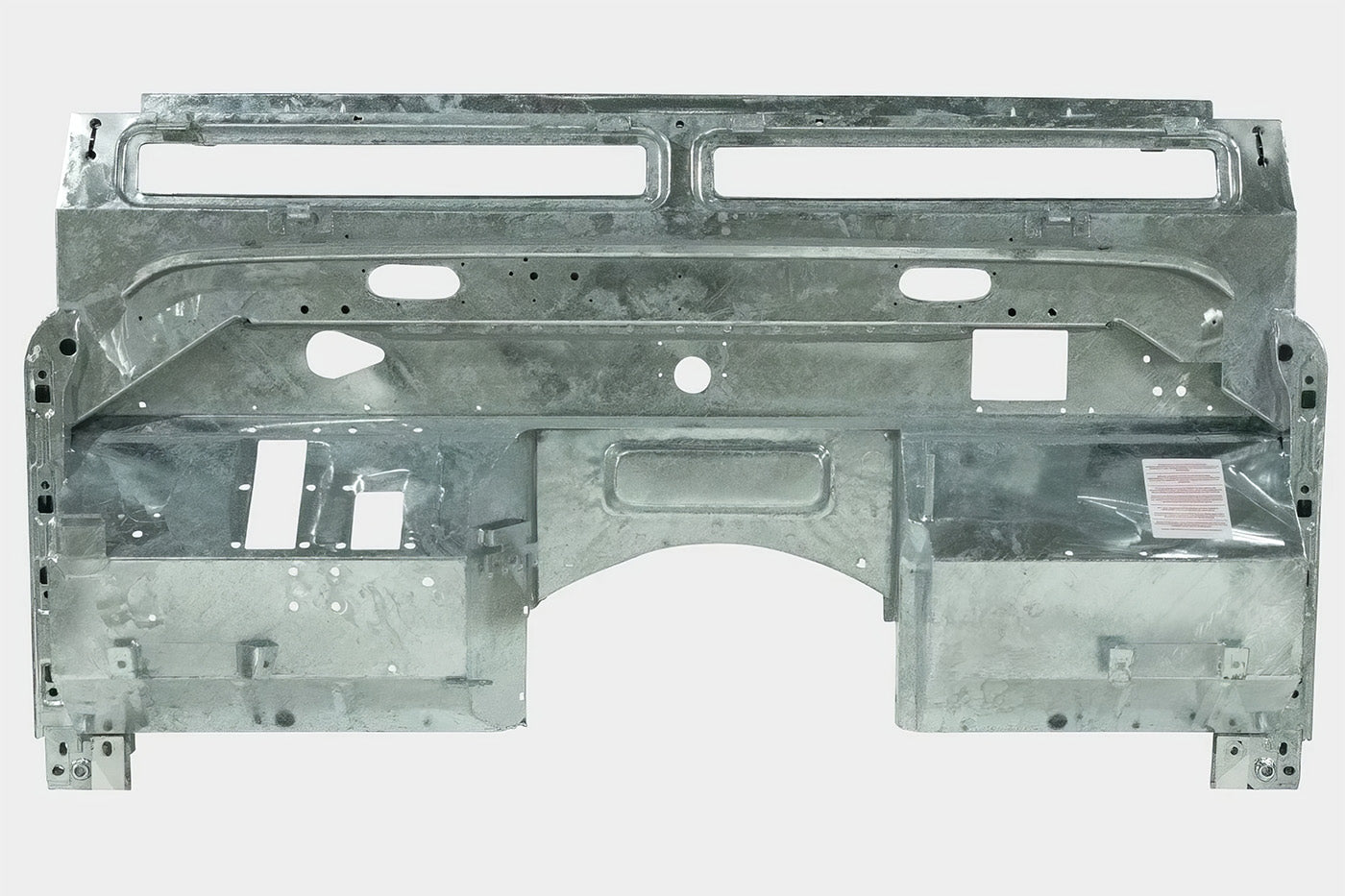

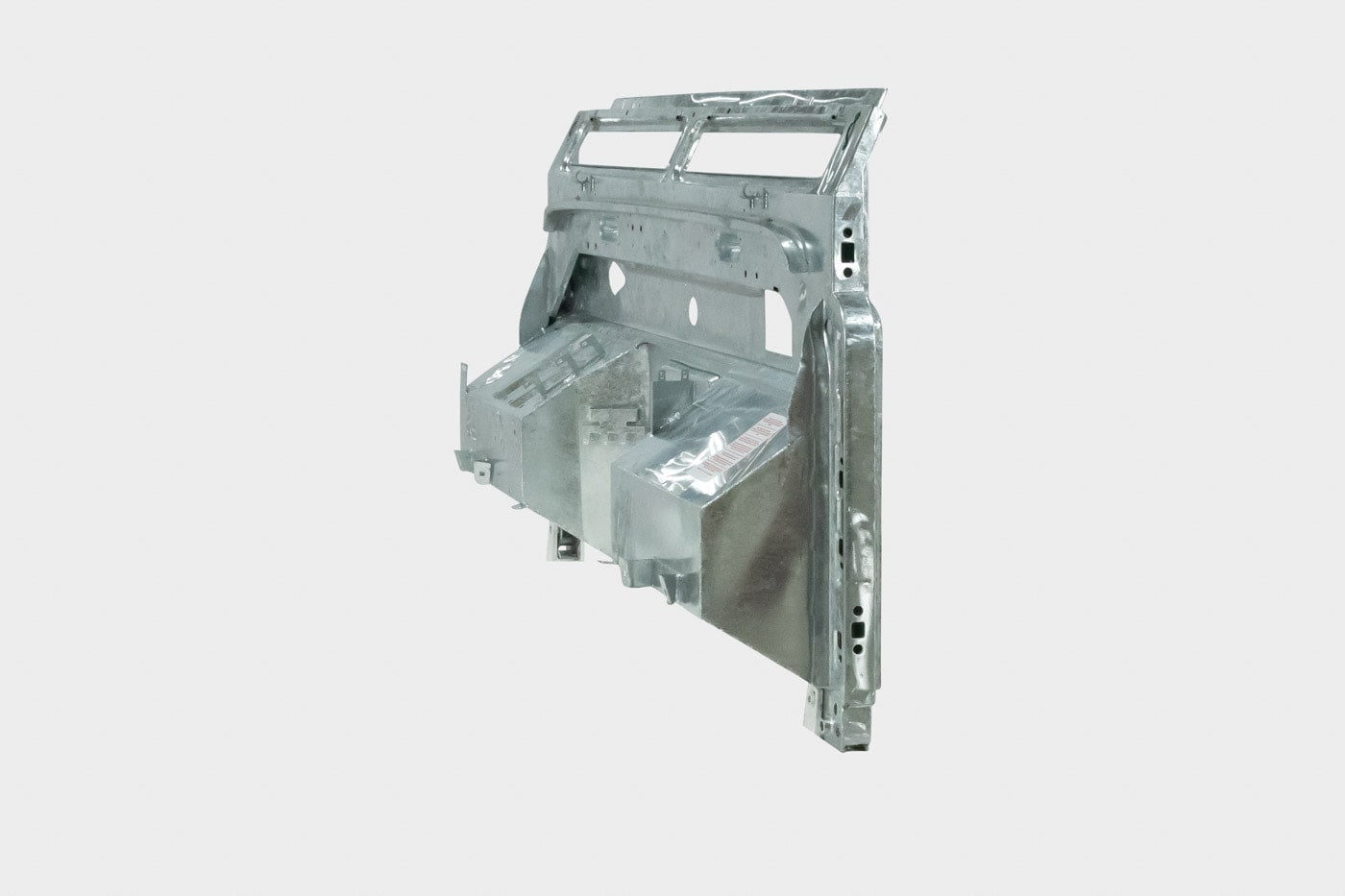

Defender 90 200Tdi / 2.5TD / 2.5NA Galvanised Bulkhead

EU Customer Pricing Click Here

Most items are In-stock

-

100 Day Returns - Offering you a worry free purchase

WORKMANSHIP

Quality Matches Established Brands. Price Doesn't.

WORKMANSHIP

Quality Matches Established Brands. Price Doesn't.

Having manufactured thousands of units using the same specifications as established brands, our products deliver identical quality and fit. For extra peace of mind we offer 100 Day Returns - because we're confident in our manufacturing standards.

Over 8000 units manufactured using identical British steel grades, welding standards, and dimensional tolerances as other brands. Our refined processes produce the same accurate fitting parts - without the brand markup.

We use the same materials and manufacturing processes as established competitors, but our inhouse operations mean significantly lower costs for you. Same British manufacturing excellence, same perfect fit - just smarter pricing that leaves more budget for your restoration.

Made in the UK - Galvanised finish as standard

Over 3,000 Land Rover enthusiasts have chosen our superior engineering.

Why Single-Skin is Better:

- Eliminates moisture traps between layers, resulting in superior corrosion resistance

- Withstands the galvanising process better (double-skin is more prone to distortion)

- Better than established brand alternatives - at 35% less cost due to a complete in-house manufacturing process (no middle man)

We ship worldwide from our factory and warehouse in the UK. Shipping cost is primarily based on the destination country.

Please place your order as normal and at the checkout stage a list of shipping options and pricing will be available. If a shipping cost is not available please contact us and we will provide you with a quote from our shipping partners.

We hope you will be happy with your order. However, if within 100 days from the date of delivery, you change your mind, we will be happy to offer you a refund credited to the payment method used in the original sales transaction.

Please be aware of the following terms that apply when requesting a refund and return of your original order items to us:

Items must be returned unused and in a resalable condition.

When returning your items, all arrangements and shipping costs are your responsibility.

Read our full Returns & Refunds Policy here

All Shielder chassis and bulkheads come with a 5 year non-transferable manufacturers warranty covering the integrity of the item for a period of 5 years from the date of purchase.

We warrant that under normal use, outside of any accident or misuse or overloading the chassis or bulkhead will not fatigue or fail to be able to perform its normal duties safely.

Impact Fabrications LTD TRADING AS Shielder Chassis will not be liable for any consequential loss in connection with a claim on this warranty, including recovery fees or onward travel costs.

Keeping Standards High

A replacement chassis and bulkhead are the most structurally integral components of your Land Rover. All Shielder products are manufactured to meet UK and EU engineering standards and have been subjected to the most stringent of tests.

Each product is covered by an Insurance Approved Certificate of Conformity. The result is peace of mind to you, knowing your Land Rover is restored using the highest quality components.

Item + Delivery Cost to EU Country

If your country is not listed please call us on +44 (0)151 453 6725

All prices are listed in Pounds Sterling GBP. Our store will convert prices to Euro during checkout.

This table shows the total amount you pay delivered to your door. (no additional fees)

| Country | EU VAT registered business | EU Private individual (Not VAT registered) |

|---|---|---|

| Price shown is for a standard item with no extras | ||

| Ireland | £1100 | £1320 | Spain | £1300 | £1560 |

| Portugal | £1300 | £1560 |

| Belgium | £1210 | £1452 |

| France | £1210 | £1452 |

| Germany | £1210 | £1452 |

| Luxembourg | £1210 | £1452 |

| Netherlands | £1210 | £1452 |

| Austria | £1300 | £1560 |

| Bulgaria | £1300 | £1560 |

| Croatia | £1300 | £1560 |

| Czechia | £1300 | £1560 |

| Estonia | £1300 | £1560 |

| Greece | £1300 | £1560 |

| Hungary | £1300 | £1560 |

| Latvia | £1300 | £1560 |

| Lithuania | £1300 | £1560 |

| Poland | £1300 | £1560 |

| Slovakia | £1300 | £1560 |

| Slovenia | £1300 | £1560 |

| Switzerland | £1300 | £1560 |

| Italy | £1300 | £1560 |

| Romania | £1300 | £1560 |

| Denmark | £1350 | £1620 |

| Finland | £1350 | £1620 |

| Norway | £1350 | £1620 |

| Sweden | £1350 | £1620 |

Simplified EU Ordering Experience

Why EU customers choose Shielder Chassis

Seamless Purchasing

✅ No Customs Charges - Zero import duties or customs fees

✅ No Customs Delays - Direct shipping without border holdups

✅ Faster Delivery - Quicker transit times than mainland UK suppliers

Hassle-Free Returns

✅ Simple Process - Return items as easily as to any EU based business

✅ No Customs Forms - No export declarations needed

✅ No Return Import Fees - Avoid duties charged by mainland UK companies

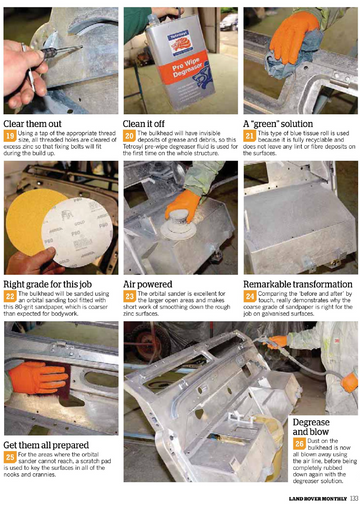

Bulkheads Re-Engineered Specifically For Galvanising

Shielder set out to manufacture new bulkheads that could be galvanised, as galvanising greatly extends the life of a metal product.

To achieve this Shielder needed to re-engineer specific sections found on the original bulkheads. The problem is, original bulkheads are double platted (sheet metal layered on top of sheet metal) in the footwells and across the middle of the bulkhead, above the transmission tunnel.

The double platting does not allow the bulkhead to be properly galvanised and instead leads to early product failure.

To overcome this problem and ensure a bulkhead can be properly galvanised Shielder re-engineered the bulkhead to have no double platted sections.

Our design is unique, and no other bulkhead on the market offers this.

Shielder bulkheads are manufactured from thicker sheet steel than the original bulkheads, 1.5mm verses 1mm. The outcome is a stronger bulkhead that can be properly galvanised with no negative impact.

ABOUT

Shielder Chassis

Impact Fabrications Limited, founder and owner of Shielder Chassis, is a family-owned business established in 1991. We started manufacturing steel products for specialist industries and now focus solely on Land Rover parts.

As Land Rover owners and enthusiasts ourselves, we understand the financial reality of restoration projects. That's why we engineered our business differently - inhouse operations, direct-to-customer sales, and fair pricing that doesn't compromise on quality.

We use the same British steel grades, manufacturing standards, and quality controls as other established brands, but without the markup. Because we believe Land Rover restoration should be about passion, not paying inflated prices for identical products.